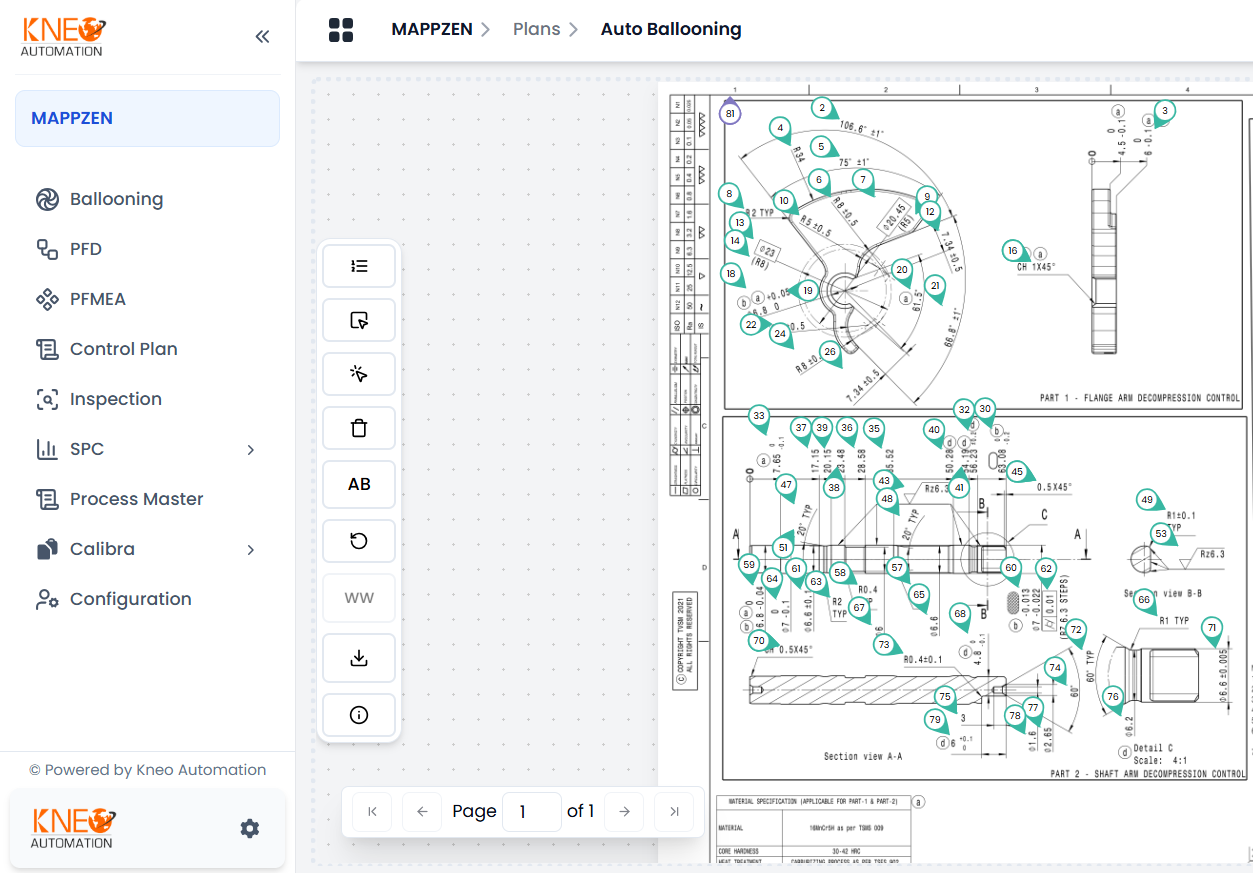

Auto Ballooning

Software

Automate Drawings. Eliminate Manual Errors. Accelerate APQP & PPAP.

Auto Ballooning is an intelligent software tool designed to automatically identify, number, and balloon critical dimensions from engineering drawings—reducing effort and eliminating mistakes.

Built for manufacturing, quality engineers, and design teams, it forms the foundation of digital APQP and links directly with Control Plans, PFMEA, MSA, SPC, and PPAP workflows.

Whether you are preparing inspection reports, FAI documentation, or customer submission files, Auto Ballooning helps you work faster, smarter, and with complete accuracy.

Why Auto Ballooning?

Manual ballooning is slow, repetitive, and error-prone. Engineers spend hours reviewing drawings, marking characteristics, numbering features, then mapping them to inspection sheets.

Auto Ballooning transforms this into a one-click digital process, enabling:

Key Features

Automatic Dimension & GD&T Detection

The software scans engineering drawings (PDF/DWG) and automatically identifies:

Each characteristic is ballooned instantly and mapped to a unique characteristic ID.

Smart Balloon Numbering

Intelligent sequencing logic that automatically organizes and formats balloon numbers according to your standards.

This ensures complete consistency across inspection sheets, control plans, and PPAP documents.

Automated Characteristics Table Generation

Once ballooning is complete, the software automatically generates a Characteristic/Inspection Table, containing:

This table seamlessly populates downstream quality documents.

One-Click Integration With MAPP ZEN Modules

Auto Ballooning is fully integrated into the MAPP ZEN Quality 4.0 ecosystem, allowing direct mapping into:

This ensures a single source of truth for all product characteristics throughout the APQP lifecycle.

Support for Any Drawing Format

Process any engineering drawing type with our versatile engine, ensuring compatibility with your existing CAD workflows.

The system optimizes balloon placement automatically, even for complex drawings.

Revision Control & Version Management

When a drawing is revised (e.g., Rev A → Rev B), the system automatically analyzes both versions and provides a detailed breakdown of all changes.

Perfect for industries with frequent engineering updates.

FAI, PPAP & Customer Submission Ready

Auto Ballooning auto-generates submission-ready documentation including:

All aligned with AIAG & IATF guidelines.

Easy-to-Use Web Interface

A modern, browser-based platform designed for instant team adoption without complex IT installation.

Teams can collaborate online, review ballooned drawings, and approve them instantly.

Business Benefits

80% Reduction in Time

Instant extraction eliminates hours of manual work for ballooning & inspection planning.

Zero Errors

Quality documentation stays consistent across FMEA, Control Plans, and PPAP.

Faster APQP Cycles

Speeds up new part introduction, engineering changes, and customer submissions.

Higher Compliance

Aligned with AIAG/IATF requirements and industry best practices.

Seamless Integration

Part of a unified, closed-loop quality ecosystem (MAPP ZEN).

Ideal For

Automotive OEMs & Tier Suppliers

Aerospace & Defense

General Manufacturing

Fabrication & Machining

Plastics, Forging, Casting, Sheet Metal

Electronics & Industrial Equipment

Ready to Transform Your Quality Documentation?

Experience the power of automated ballooning and accelerate your APQP process today.