MAPP VISION

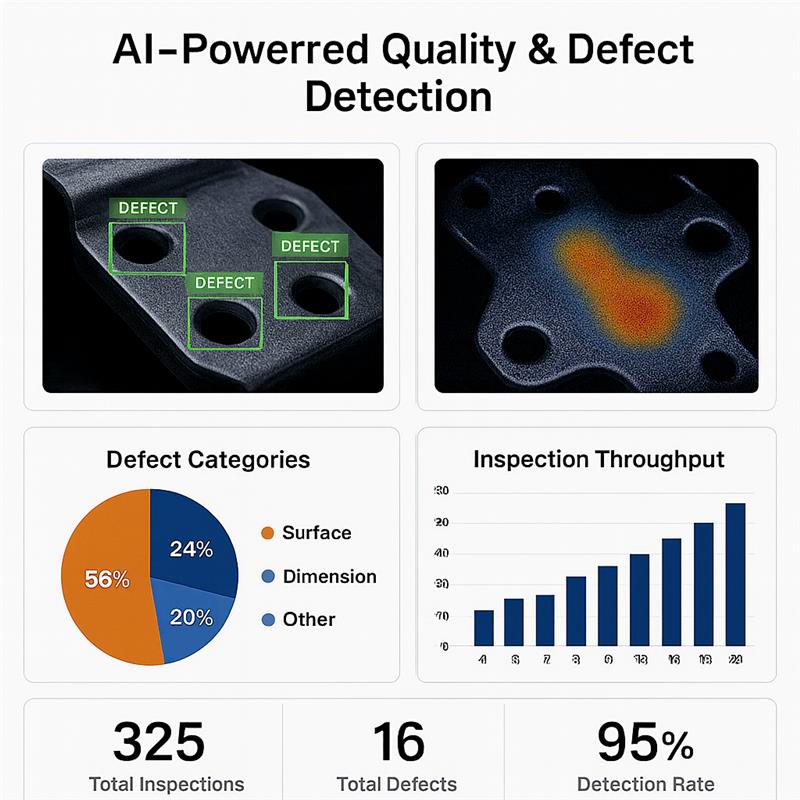

AI-Powered Quality & Defect Detection

Modern manufacturing demands zero-defect quality with real-time feedback to operations. MAPP Vision is an advanced, AI-driven machine vision module that automatically detects quality issues, guides operators, and seamlessly integrates with your automation and MES ecosystem.

Designed to work natively with PLCs, robots, and the MAPP ZEN Quality 4.0 module, MAPP Vision brings intelligence, speed, and accuracy to every inspection point on the shop floor.

Key Capabilities

Defect Detection & Classification

Identify scratches, dents, misalignments, missing parts, wrong orientation, labeling issues, surface defects, and more using rule-based or AI-based inspection.

AI Model Training & Controlled Model Improvement

Models can be retrained or refined manually whenever new defect images or scenarios are added, ensuring full control over updates and predictable inspection performance.

High-Speed Real-Time Processing

Designed for cycle-time-critical applications—process images and trigger PLC outputs instantly.

On Premises Deployment

Inspections are executed directly on a local PC or server, ensuring fast processing, secure data handling, and seamless integration with existing plant infrastructure.

Seamless Integration With Shop-Floor Systems

Direct PLC Integration

MAPP ZEN (Quality 4.0) Integration

Built for Manufacturing Reliability

Where MAPP Vision Delivers Impact

Automotive BIW, powertrain, plastics, electronics, FMCG, machining, welding

Assembly verification

Surface defect detection (metal, plastic, painted parts)

Dimensional checks

OCR/Barcode validation

Packaging quality checks

Business Benefits

Zero-Defect Quality Culture

Achieve consistent quality standards across all production lines

Reduced Manual Inspection

Lower dependency on manual inspection and human error

Lower Rework & Scrap

Reduce costs through early defect detection

Faster Issue Resolution

Quick identification and resolution of customer quality issues

Complete Traceability

Image evidence for every inspection with full audit trail

Increased Line Uptime

Automated decision-making improves production efficiency

Optional Add-On Capabilities

Ready to Achieve Zero-Defect Quality?

Transform your quality inspection with AI-powered vision technology and real-time defect detection.