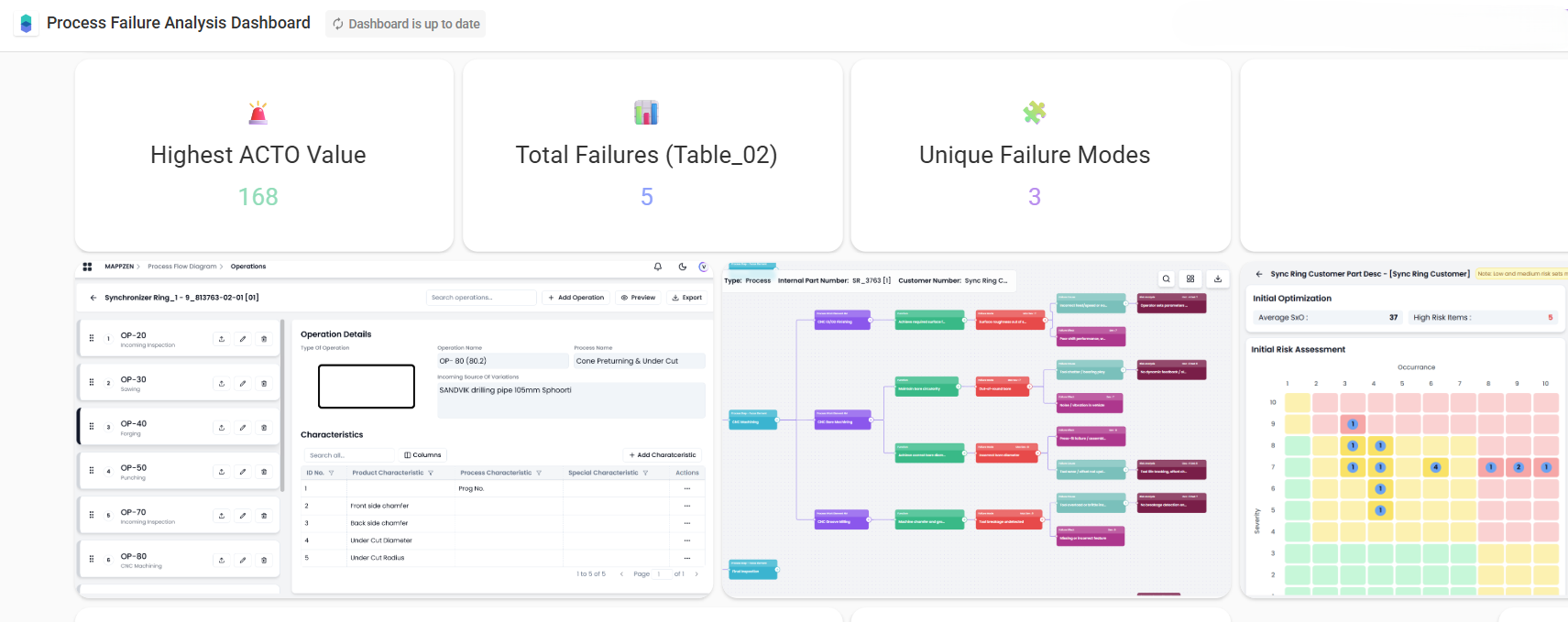

PFMEA Software

Proactive Risk Prevention

Prevent Failures Before They Happen. Strengthen APQP. Improve Process Reliability.

PFMEA is essential for building reliable and defect-free manufacturing processes. Our PFMEA Software helps teams digitize, standardize, and accelerate PFMEA creation— fully aligned with AIAG-VDA guidelines.

Built for automotive, aerospace, and high-precision industries, it helps reduce risk, eliminate inconsistencies, and strengthen your APQP workflow.

Why PFMEA?

Traditional PFMEA in Excel is slow, inconsistent, and error-prone. Our PFMEA platform solves this with guided, structured, and collaborative digital workflows built for high-quality manufacturing.

Challenges With Traditional PFMEA:

Key Features

AIAG-VDA Structured PFMEA Workflow

The software follows the 7-step AIAG-VDA methodology to maintain global compliance and ensure structured creation.

All steps are guided and auto-formatted per AIAG-VDA guidelines.

Hierarchical Process Mapping (Process Tree)

Visually map the entire manufacturing process to ensure no operation, station, or sub-process is missed during analysis.

The process tree forms the backbone for accurate failure mode analysis.

Automated Function & Failure Mode Suggestions

AI-assisted recommendations help engineers build PFMEAs faster by suggesting relevant failure modes and effects.

Greatly reduces repetitive work and improves PFMEA standardization.

Integrated Severity, Occurrence & Detection Ranking

Apply ratings using built-in AIAG-VDA compliant S, O, and D tables with automated Action Priority (AP) calculation.

Ensures zero manual calculation mistakes and consistent scoring.

Closed-Loop Action Tracking & Optimization

Turn PFMEA into a living document with actionable, trackable tasks for reducing risks and verifying effectiveness.

Ensures risk reduction efforts are executed, tracked, and validated.

Auto-Linking With Control Plan, MSA & Process Flow

Seamless integration inside the MAPP ZEN ecosystem ensures all quality documents stay synchronized in real-time.

Creates a single, unified source of truth across APQP.

Real-Time Collaboration & Version Control

Designed for global, multi-plant operations needing strict traceability, access control, and audit logs.

Ideal for distributed teams and customer/audit compliance.

Template Library for Faster PFMEA Creation

Build and reuse templates for standardized processes (welding, molding, etc.) to significantly reduce creation time.

Accelerates PFMEA creation by 50–70% while enforcing standardization.

Auto-Generated AIAG-VDA Compliant Reports

Instantly produce auditor-ready reports directly from the system, formatted exactly to industry standards.

Ideal for PPAP submissions and customer audits.

Business Benefits

Stronger Risk Prevention & Reduced Defects

Identify and mitigate failure modes before they reach production.

Faster, Standardized PFMEA Development

Reduces engineering effort by up to 60% compared to Excel.

Perfect AIAG-VDA Compliance

Documentation remains audit-ready at all times.

Closed-Loop Quality Management

PFMEA becomes an active improvement tool rather than a static document.

Lower COPQ & Warranty Costs

Improves long-term reliability and product performance.

Ideal For

Automotive OEMs & Tier Suppliers

Aerospace & Defense

Heavy Engineering & Machinery

Plastics, Casting, Forging, Machining

Electronics & Assembly

Any process with high quality or safety impact

Transform Your PFMEA Process

Build reliable, repeatable, and optimized manufacturing processes with a PFMEA solution designed for next-generation quality teams.