Factory Monitoring: Unlocking Visibility of the Production Process

In the heart of modern industries, factory monitoring has appeared as a beacon of efficiency, enabling businesses to get unparalleled insights into their processes and production. Let’s explore this game-changing practice and discover how it’s transforming the way industries operate.

Factory monitoring changes the game by providing real-time visibility into every corner of your operations. From production lines to inventory management, from machinery health to employee performance, visibility becomes the driving force behind informed decisions.

Streamlining Processes with Data-Driven Insights

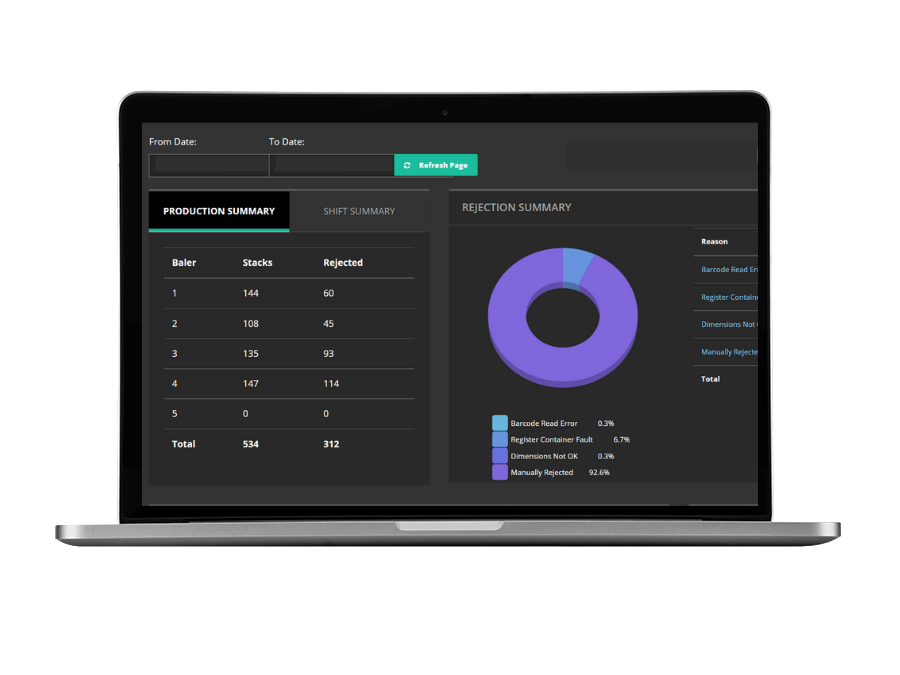

Imagine having a dashboard that assembles all the relevant data from your factory operations. Factory monitoring systems do exactly that, gathering data from different sources and presenting it in a coherent format. This data isn’t just numbers; it’s the breadcrumbs that lead to process optimization. Recognizing bottlenecks, identifying trends, and understanding resource allocation become easier than ever before, paving the way for streamlined processes.

Precision in Production Planning

Effective production planning depends on precise information. Factory monitoring enables you with real-time data on machine uptime, downtime, and output rates. With this data at your fingertips, you can adjust production schedules on the fly, allocate resources wisely, and assure that deadlines are met with precision. The result? Minimized waste, improved efficiency, and increased customer satisfaction.

Predictive Maintenance

Maintenance is an essential part of manufacturing but needs significant time and effort. Use the power of predictive maintenance with the MAPP VITA (Maintenance Module) and optimize maintenance activities. Boost overall productivity by reducing non-productive loss of time, increasing worker safety, and reducing maintenance costs.

A Safer, Smarter Work Environment

The safety of your workforce is paramount. Factory monitoring extends its benefits to the realm of safety by alerting managers to potentially hazardous situations. From detecting abnormal emissions to monitoring compliance with safety protocols, these systems contribute to creating a secure working environment where employees can perform at their best without unnecessary risks.

Real-Time Decision-Making

In the fast-paced industrial landscape, delays in decision-making can have significant consequences. Factory monitoring enables real-time decision-making by providing up-to-the-minute insights. Whether it’s adjusting production targets, reallocating resources, or responding to unexpected challenges, having precise data in real time enables managers to make the right calls swiftly.

Embrace the Future of Factory Management

Factory monitoring isn’t just a trend; it’s a transformative practice that’s rewriting the rules of the industrial game. The era of guesswork and uncertainty is fading away, replaced by a data-driven approach that improves efficiency, reduces waste, and promotes a culture of continuous improvement.

In Conclusion

In a world driven by data, factory monitoring stands as a beacon of clarity among the complexities of industrial operations. Production visibility is now a necessity for businesses that aim to thrive in the competitive landscape. Are you ready to see your factory in a new light?

Embrace the power of factory monitoring and move toward a more efficient and productive future.