How a Digital Shop Floor Management Platform Improves Your OEE

With COVID-19, making the digital shift even more important, it’s time to say goodbye to manual and paper workflows in mass production factories. Now its time to move towards Digital Shop Floor Management! Digitization is the way to go with Industry 4.0 as this is key to overall equipment efficiency worldwide (85%). In fact, as per Deloitte, 73 % of U.S. factories were moving ahead with Smart Factory initiatives as of late 2019.

OEE is a lean-to-continuous improvement metric measuring the 3 critical manufacturing pillars of Availability, Performance and Quality. An OEE score is described as a %.

The efficient way to calculate OEE is:

OEE% = Availability x Performance x Quality

This score is used to describe the overall efficiency of a single machine, a production line, or an entire shop floor. It provides an indication of manufacturing performance without requiring manufacturers to explore multiple KPIs. This is why savvy production industries are investing in digital shop floor management software to improve OEE.

Get Real-Time Performance Monitoring and Control

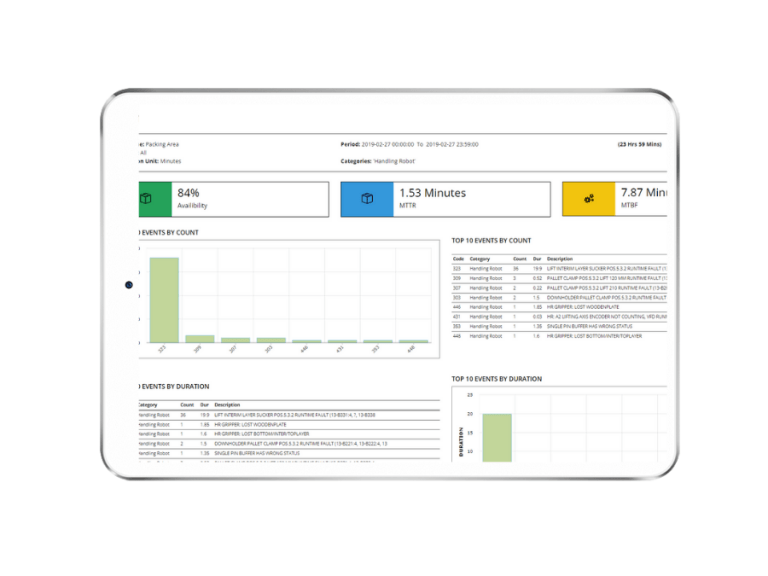

MAPP EYE gives you real-time Production Monitoring & Control by pointing to production performance concerns and allowing your team to acknowledge in the right way. As your team becomes more dynamic, concerns are managed more efficiently or eliminated completely. Features include OEE performance, faults, downtime tracking with root cause identification, tracking run time is one of the ways to get clarity of where to improve OEE. If long downtime events are being tracked often in any section of a facility, there is likely scope for improvement. Minimizing downtime and waiting periods between manufacturing processes is a simple way to improve run time (availability) and hence improve OEE.

Utilize Extendable/ Customize OEE Reports

Kneo’s MAPP platform provides out-of-the-box features. Key reports on OEE and a few other

standard performance indicators such as an MTTR (mean time to repair) & MTBF (mean time

between failure). Data is automatically gathered from control systems with little or no changes

required. Configuration of reports is easy, extendable and scalable. Additionally, you can take

benefit of powerful customization features to customize data collection formulae and

calculations. All reports can be easily accessed via a web browser across devices. From that,

you can easily check out the OEE report and take the necessary actions.

Understand in Detail Cycle Time

By tracking the time product takes to complete each cycle, we will get an average cycle time,

‘which can be utilized to calculate machine performance. The shop floor management

platform tracks the conditions related to each cycle, including the shift-wise timings, the time of

day, the product created, etc.

With this data, employees and management can recognize patterns for both the fastest as well

as slowest cycle times, allowing them to recognize problems in production. The use of this

information to reduce cycle times can significantly increase yield and OEE.

Quality Control with Floor Mapping & Order Progress

The capability to use shop floor management software to track and recognize the flow of

material through the facility and in between lines is an important part of the successful

production facility. Mapp platform collects data from equipment, and integrated systems while

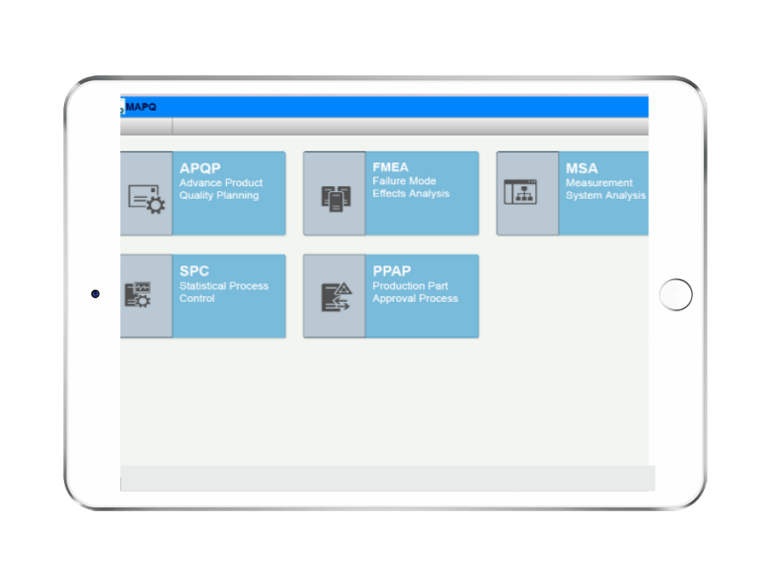

also empowering the user to track additional information. Our MAPP ZEN Quality 4.0 module

helps quality assurance through its various modules such as PFMEA & DFMEA, PPAP, APQP,

MSA and SPC.

To recognize errors as early as possible, quality is guaranteed with spot checks, SPC as well as

100% tests. This module is one place to create and maintain the product quality control plan

and recognize areas for improvement. The system alerts operators in real-time when specific

errors occur. It also allows them to act before waste is produced and itis always online for

remote monitoring.

It also enables managers to inspect operations across the shop floor in real-time via an

interactive dashboard. Plan, schedule, allocate, analyze, and track operator tasks and machine

efficiency on the go.

Implement Kneo’s Online SPC software module, along with the quality module, to:

1. Get real-time SPC analysis to assure your process is stable

2. React quicker when process irregularities arise

3.Generate process inspection reports

4. Forecast the amount of non-conforming product

5. Minimize material costs

If each and every step throughout the production is mapped and analyzed then inefficient floor

layouts can be easily recognized. Looking for more efficient routes for products to travel—or

even rearranging the facility floor completely to give a better flow—can help save time and

minimize average cycle times (performance), therefore improving OEE.

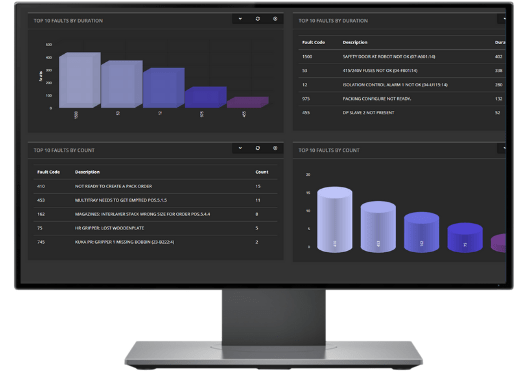

Root Cause Analysis

One of the most powerful ways to reduce deviations and positively impact your OEE is with

digital Root Cause Analysis. Going down to the root of the issue makes sure you avoid

repetition. Repeat concerns lead to waste—in the form of scrap, time as well as resources spent

on resolving the problem, downtime and product rework. Removing waste always results in

productivity benefits. When your engineers analyzed root causes remotely via a single

database, there is no requirement to send your engineers or safety experts all over the world

anymore, potentially unlocking remarkable cost savings in time.

Smart Factory Visual KPI Displays

MAPP IIOT Platform gives you a clearer picture of the whole factory floor with visual KPI

displays. This approach can be applied at the shift, operator, or machine level to “check” what is

going on that is impacting OEE. Operators can utilize this visualization to adjust and further

improve their machine performance. This allows your team to become more proactive and

respond to concerns in the right way. For example, various parameters can be seen such as

current process status, production status, project target status, faults, etc. Our digital Shop floor

Management solution will add more value to your existing system: Using customizable KPls,

deviations in capacity utilization & damage can be identified early on, which can be quickly

resolved. This not only improves the OEE but also gives all employees a clear overview of

production through standardized processes.

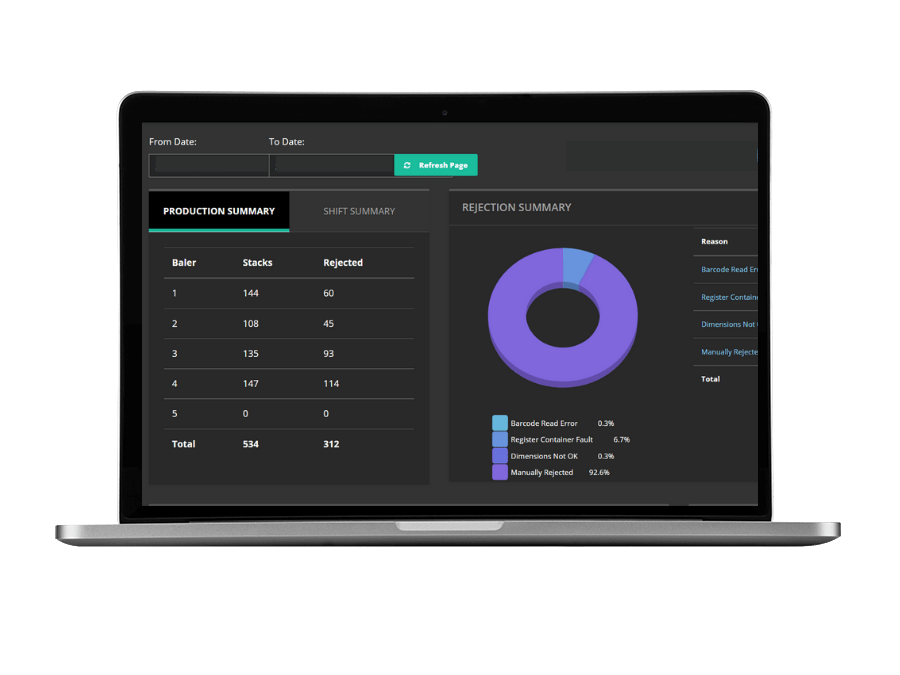

Production Tracking

Along with tracking products generated, it is also essential to document the number of

defective products generated. Tracking defective products produced will also recognize under

which circumstances they were produced.

Knowing where and when the most defective products are generated may specify where

‘machine maintenance is required, which help to minimize the manufacturing losses. Minimizing

the number of defective products generated will automatically improve quality, resulting in an

increase in OEE.

This way, you can optimize your production capacity and usage through transparency. MAPP

platform gives up-to-date, complete information in a graphically understandable format and can

create forecasts based on historical data.

With our digital solution for shop floor management, we support you in improving overall

equipment efficiency (OEE) in long term. To start with this first you need to analyze where you

currently stand.